How are Chocolate Chips Made in a Factory? 4 Steps

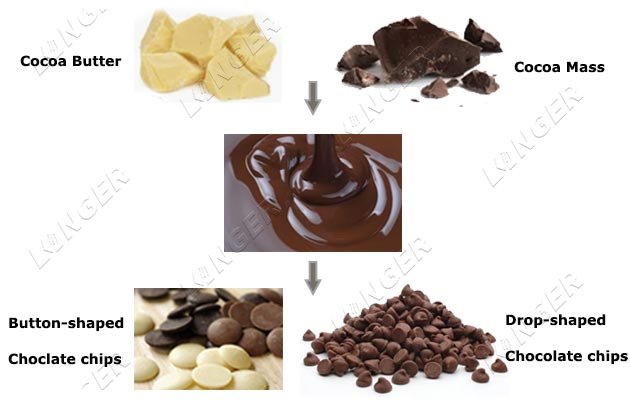

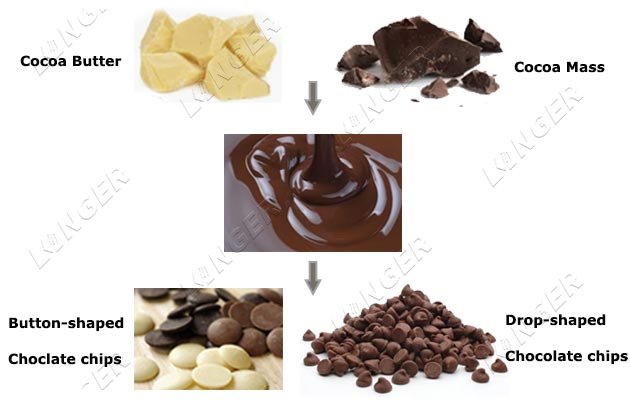

Chocolate chips are divided into drop-shaped and button-shaped, and are decorated with various foods, such as biscuits and cakes. So how are chocolate chips made in a factory? Here are four steps and the necessary equipment.

Step 1 - Melt cocoa butter, cocoa mass

The cocoa liquor block or the cocoa butter is put into the melting oil pan, and the inner pot of the melting oil pan is conducted by hot water, so that the solid cocoa butter absorbs heat and melts into a cocoa butter liquid.

Step 2 - Conching

Use professional equipment, chocolate conche machine. It can achieve finely ground chocolate slurry with an average fine particle size of 20um.

Step 3 - Tempering

Chocolate tempering machine, this is an indispensable device in the chocolate factory.

The temperature control center is divided into multiple layers and divided into four temperature zones according to the temperature control requirements. It can strictly control the different temperatures required by the chocolate slurry in each process stage.

Step 4 - Depositing

Chocolate chips making machine is a special equipment for producing chocolate chips.

Through the pouring head, the chocolate slurry is directly poured into a drop-shaped, button-shaped and other types of chocolate chips on the PU conveyor belt, and enters the cooling tunnel. After cooling, it automatically falls off.

Video of How Chocolate Chips are Made?

The above are the four steps of making chocolate chips in the factory and the video display. For more chocolate information, please contact:

Email: serena@machinehall.com

Whatsapp/Mobile: +8615515597212

Message