How is Chocolate Made from Cocoa Beans in Factories?

Chocolate is a popular food all over the world. It is also an important auxiliary product, which is used to make all kinds of snacks and desserts. But people don't know how complicated it is to make chocolate. So in the chocolate factory, how is chocolate made from cocoa beans? This article will be introduced in detail from three stages.

First Stage: Make Cocoa Liquor from Cocoa Bean

First Stage: Make Cocoa Liquor from Cocoa Bean

1. Cleaning:

The cocoa beans purchased at the chocolate factory usually contain some impurities, so put them in the washing machine to remove the sand, dirt and stones, and then use metal detectors to detect the metal and remove it.

The cocoa beans purchased at the chocolate factory usually contain some impurities, so put them in the washing machine to remove the sand, dirt and stones, and then use metal detectors to detect the metal and remove it.

2. Roasting:

The roasting process reduces the content of cocoa beans to 5-7%, changes the color and produces rich chocolate flavor.

3. Peeling:

The roasting process makes the cocoa skin brittle, and the peeling process removes it. Remove the germ and crush the cocoa bean into small nibs.

4. Grinding:

After grinding and heating, cocoa nibs will become flowing paste, which will become "cocoa mass". After cooling, it will form hard block, which will become cocoa liquor (using the cocoa grinding machine). Adding various secondary materials to cocoa liquor will form various flavors of chocolate.

Second Stage: Make Cocoa Butter and Cocoa Powder from Liquor

1. Pressing:

Cocoa granules contain about 55% fat. Cocoa butter can be extracted from cocoa liquid by pressing and decolorizing. It has a beautiful and unique fragrance and becomes a necessary raw material for chocolate production.

2. Crushing and Cooling:

After the cocoa butter is squeezed out by hydraulic pressure, the remaining block is called cocoa cake. The cocoa cake is ground and cooled to form "cocoa powder".

Third Stage: Make Finished Chocolate Product

1. Melting:

Cocoa liquor and cocoa butter are solid at room temperature, so they need to be melted before they are mixed with other raw materials, and then they can be mixed and finely ground. After melting, the temperature should not exceed 60 ℃. The heat preservation time after melting shall be shortened as far as possible and shall not be too long.

2. Conching:

The liquid chocolate is turned repeatedly by the roller for a long time in the conche machine, and the result of collision and friction is fine, smooth, harmonious and unique taste.

3. Tempering:

Temperature regulation can make the cocoa butter crystal in the slurry form stable crystal with luster and extend the shelf life of the product.

4. Moulding:

The chocolate sauce is poured into a model with a certain size and shape, and then cooled and solidified reasonably to a solid chocolate with good luster, a certain shape and a certain weight.

5. Packaging:

Choose the right high-quality packaging machine to pack chocolate for storage, transportation and sale.

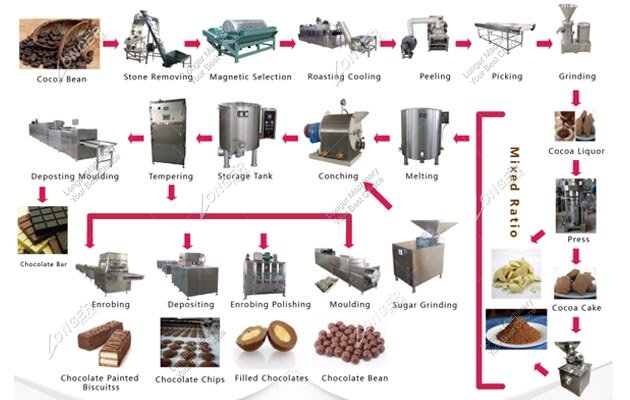

Process Flow - How is Chocolate Made from Cocoa Beans in Factory?

Process Flow - How is Chocolate Made from Cocoa Beans in Factory?

If you are interested in price and details of chocolate making machines, welcome you contact us:

Email:serena@machinehall.com Whatsapp/Mobile: +8615515597212

Message