How is peanut butter manufactured automatically?

Peanut butter production line, on the basis of the introduction of foreign technology, combining with the condition of our country under the studying of technical personnel, is developed and researched new generation of products with advanced, practical, cheap features. The whole line is all automated assembly line, can save a lot of human resources, large extent reduce the production cost, can be customized according to customer's production size.

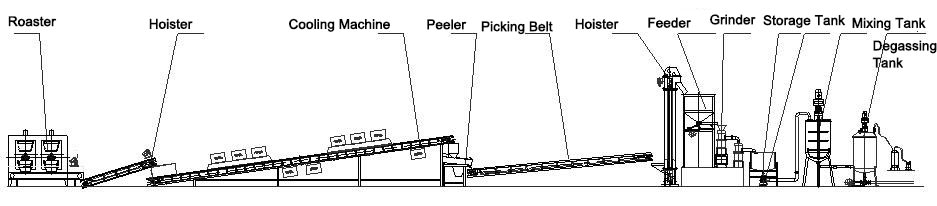

Briefly technological process: Roasting peanuts - Cooling - Peeling the red skin - Coarse grinding - Fine grinding - Degassing - Cooling - Packing.

Key points:

Baking: Heat the peanut oven to 160 ℃, keep 40-60 minutes, ensure peanut kernel inside and outside have the same color, no anxious burnt phenomenon.

Good cooling and sieving: Discharge roasted peanut rapidly, cooling, use peanut peeling machine peeling the red coat after cooling, sieving, separate the cotyledon and germ.

Grinding paste: Grinding peanut kernel into sauce, first coarse grinding, ground into a medium fineness, second fine grinding, ground into a fine smooth finished product. In the second when grinding paste add sugar or salt (sugar is 2%-3%, salt of 0.5%) and 0.05% of vitamin E.

Homogenization: In mixing pot, heat peanut butter to 60-70 ℃, and add 2% Monostearin fat and 1%-5% of soybean protein powder, mix evenly.

Canning, freezing: Put the peanut butter into the jar, let stand around at 0 ℃ low temperature freezing. After the overall crystallization, just can move. Later, can be put in room temperature preservation.

Message