Key Points of Peanut Butter Manufacturing Technology

Peanut butter is made from high-quality peanuts, rich in nutrients, and has a strong aroma of roasted peanuts. The complete peanut butter processing flow is complex, involving dozens of processes, and there are also some core technical points that need to be strictly controlled. Therefore, peanut butter is usually mass-produced by some peanut processing plants, and then sold to consumers in supermarkets or stores. Today let's take a look at these key points of peanut butter manufacturing technology.

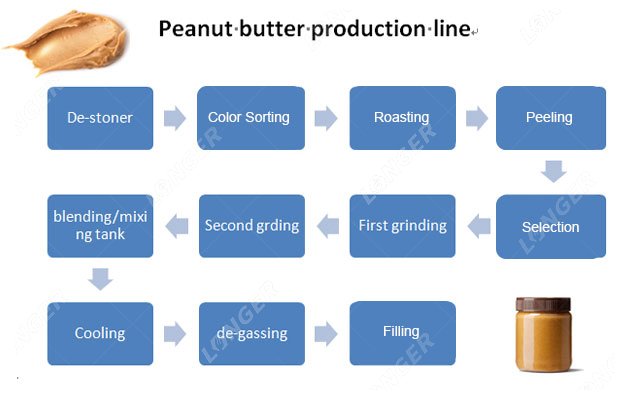

Peanut Butter Processing Technology:

Stone removal - color sorting - roasting - cooling - peeling - selection - coarse grinding - fine grinding - blending - cooling - degassing - filling

Key Points of Peanut Butter Manufacturing Technology

1. Color sorting, aflatoxin detection

In the peanut butter manufacturing plant, the aflatoxin content in the finished peanut butter can be controlled mainly by removing moldy peanuts in time through the color sorter. In addition, we can also detect and screen out by professional food testing equipment. It can not only detect aflatoxin in peanuts, but also limit and quantitatively determine the content of aflatoxin B1 in samples, and quickly and accurately screen out peanuts with excess aflatoxin.

2. Roasting

The roasting temperature of peanuts is generally about 180 ℃, and the roasting time is about 30 minutes. The ideal roasting state is achieved when the peanut skin is darker. You can try to rub the roasted peanuts by hand to see if the roasted peanuts meet the requirements.

The roasting time and temperature will fluctuate with the moisture content and particle size of the material, so it takes many tests to find the appropriate roasting temperature and time.

3. Peeling

After roasting and cooling, the peanut peeling effect can be easily obtained by a professional peanut peeling machine. If there are red peanut skins in the residual peanut butter, it will greatly affect the taste, so it is necessary to strictly control the peeling rate of peanuts.

4. Coarse grinding, fine grinding

The peeled peanut kernels are ground into coarse sauce with a grinder, and then ground into a fine sauce through the second grinding machine. The fineness of peanut butter usually needs to reach more than 100 meshes to have a better taste.

5. Degassing

The prepared liquid is homogenized in a homogenizer with a pressure of 40 MPa, so that the particles in the slurry are more delicate, which is beneficial to the stability of the quality and flavor of the finished product.

If you have the intention of processing peanut butter, welcome to inquire.

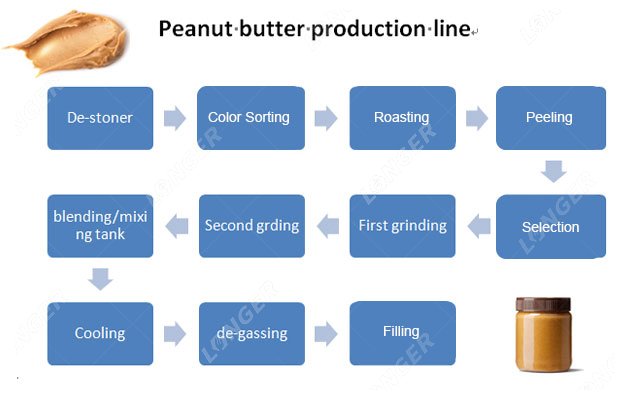

Peanut Butter Processing Technology:

Stone removal - color sorting - roasting - cooling - peeling - selection - coarse grinding - fine grinding - blending - cooling - degassing - filling

Key Points of Peanut Butter Manufacturing Technology

1. Color sorting, aflatoxin detection

In the peanut butter manufacturing plant, the aflatoxin content in the finished peanut butter can be controlled mainly by removing moldy peanuts in time through the color sorter. In addition, we can also detect and screen out by professional food testing equipment. It can not only detect aflatoxin in peanuts, but also limit and quantitatively determine the content of aflatoxin B1 in samples, and quickly and accurately screen out peanuts with excess aflatoxin.

2. Roasting

The roasting temperature of peanuts is generally about 180 ℃, and the roasting time is about 30 minutes. The ideal roasting state is achieved when the peanut skin is darker. You can try to rub the roasted peanuts by hand to see if the roasted peanuts meet the requirements.

The roasting time and temperature will fluctuate with the moisture content and particle size of the material, so it takes many tests to find the appropriate roasting temperature and time.

3. Peeling

After roasting and cooling, the peanut peeling effect can be easily obtained by a professional peanut peeling machine. If there are red peanut skins in the residual peanut butter, it will greatly affect the taste, so it is necessary to strictly control the peeling rate of peanuts.

4. Coarse grinding, fine grinding

The peeled peanut kernels are ground into coarse sauce with a grinder, and then ground into a fine sauce through the second grinding machine. The fineness of peanut butter usually needs to reach more than 100 meshes to have a better taste.

5. Degassing

The prepared liquid is homogenized in a homogenizer with a pressure of 40 MPa, so that the particles in the slurry are more delicate, which is beneficial to the stability of the quality and flavor of the finished product.

If you have the intention of processing peanut butter, welcome to inquire.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Message