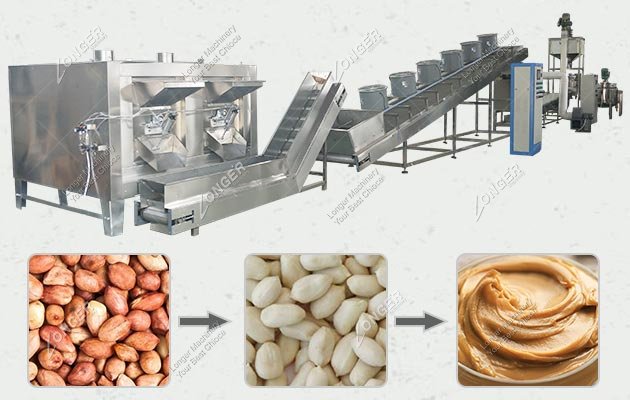

200 KG Automatic Groundnut Paste Processing Making Machine Cost

Material: Groundnut

Capacity: 200-300 kg/h

Loading Port: Qingdao Port

Description: The automatic groundnut paste processing machine can make various types peanut butter. Low cost, high working efficiency and long service life.

Product Features

This automatic groundnut paste processing machine is a small scale production line, can make 200 kg peanut butter per hour. It can produce natural type, stable type, smooth type, particle type groundnut paste and so on.

Fully automatic, high efficiency, good quality, save labor and low groundnut paste machine cost.

Groundnut Paste Production Process:

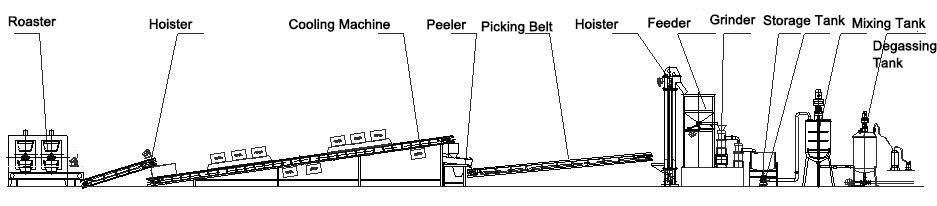

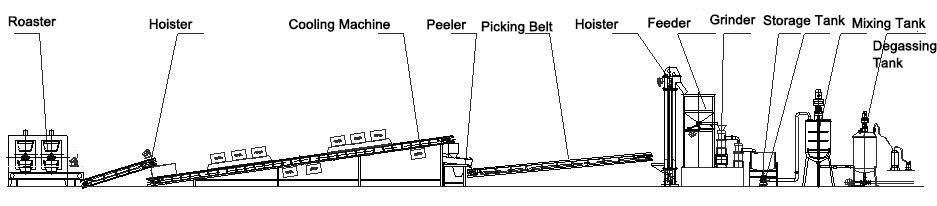

Components of Automatic Groundnut Paste Making Machine:

Groundnut roaster machine(gas or electric heating), hoist, conveyor belt, peanut peeling machine, continuous cooling machine, continuous grinding machine, mixing pot and vacuum degassing tank.

The output and size of these machines can be customized according to the requirements of customers. If the customer needs it, our engineers can also design the whole groundnut butter processing line according to the customer's factory, field survey.

Process Flow of Groundnut Paste Processing Machine Cost:

Working Video of Groundnut Paste Making Machine in China:

Fully automatic, high efficiency, good quality, save labor and low groundnut paste machine cost.

Groundnut Paste Production Process:

Components of Automatic Groundnut Paste Making Machine:

Groundnut roaster machine(gas or electric heating), hoist, conveyor belt, peanut peeling machine, continuous cooling machine, continuous grinding machine, mixing pot and vacuum degassing tank.

The output and size of these machines can be customized according to the requirements of customers. If the customer needs it, our engineers can also design the whole groundnut butter processing line according to the customer's factory, field survey.

Process Flow of Groundnut Paste Processing Machine Cost:

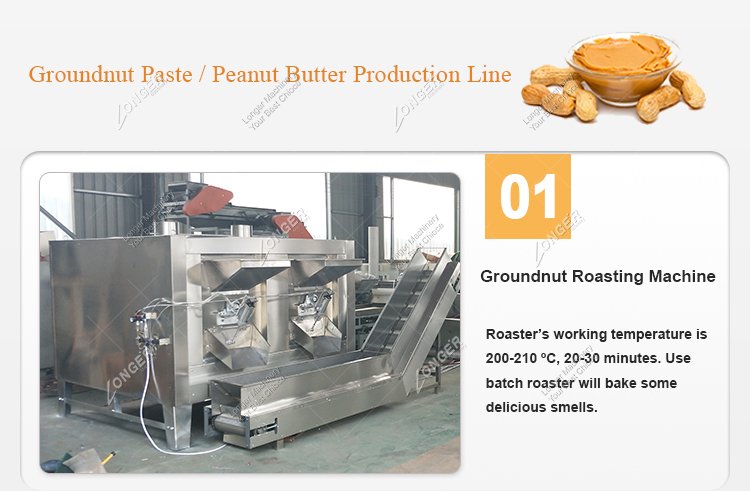

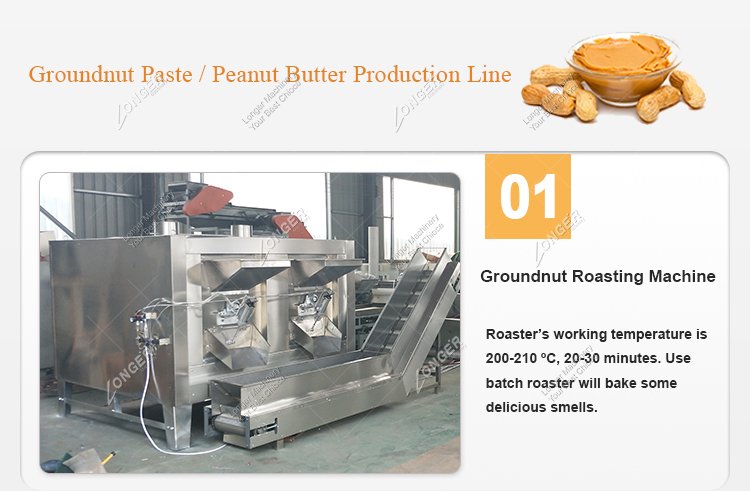

- Roasting:

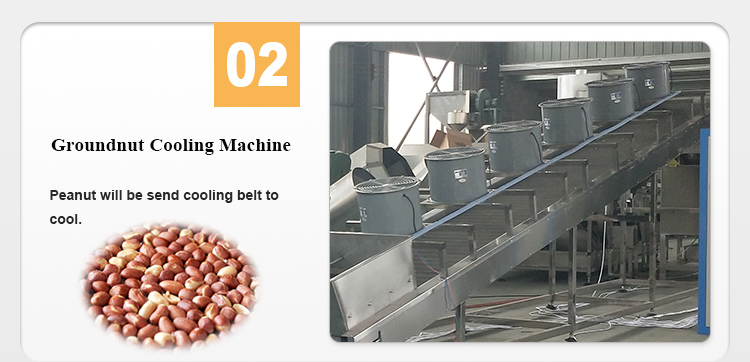

- Cooling:

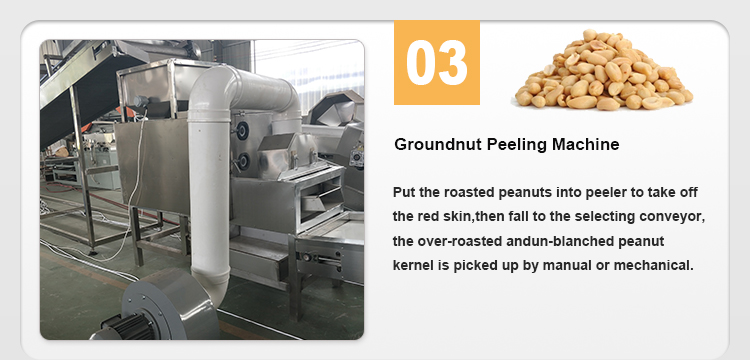

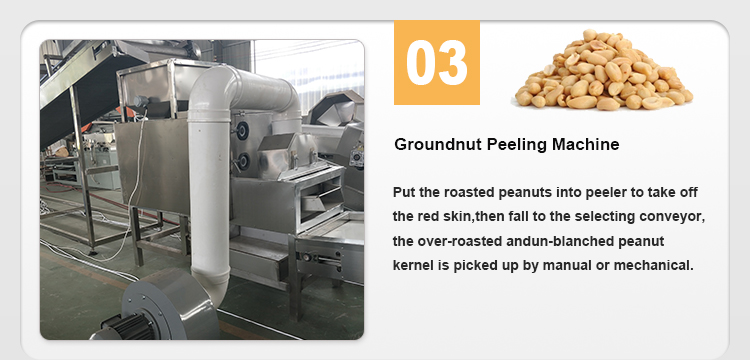

- Peeling:

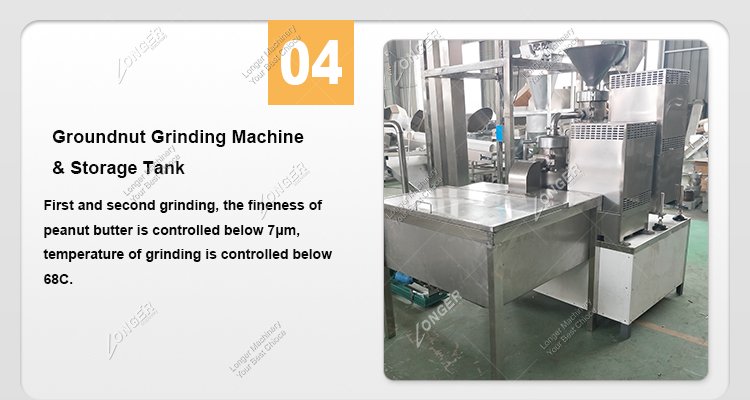

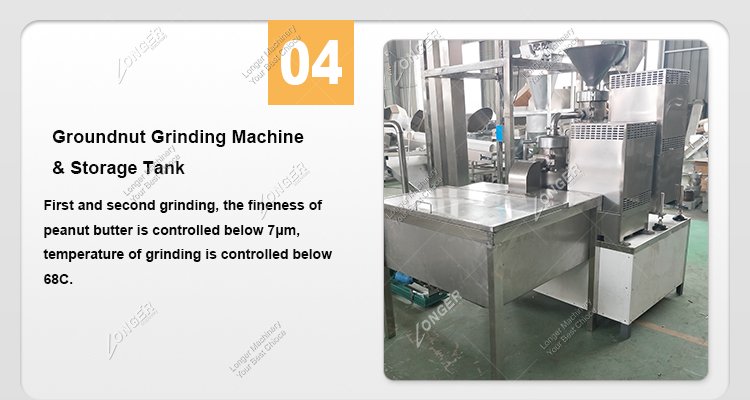

- Primary grinding:

- Second grinding:

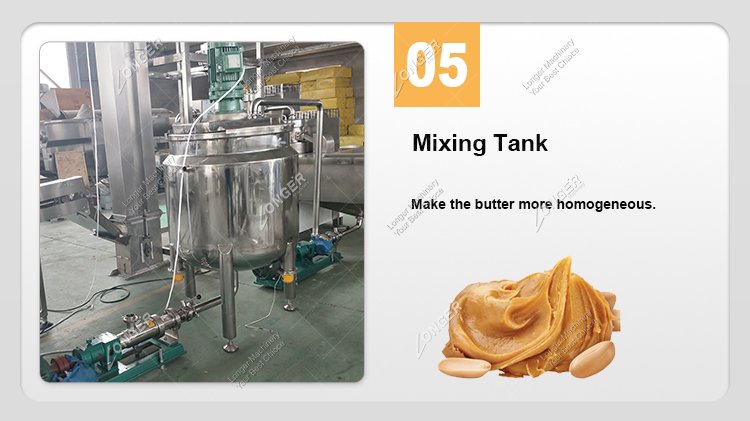

- Mixing:

- Cooling:

- Degasser:

- Storage tank:

Working Video of Groundnut Paste Making Machine in China:

Technical Data

| No. | Name | Power(kw) | Size(mm) |

| 1 | Baking machine | 70.8 | 3000*2900*1650 |

| 2 | Conveyor belt | 0.75 | 2400*500*500 |

| 3 | elevator belt | ||

| 4 | Cooling Belt | 3 | 10000*1000*1700 |

| 5 | Peeling machine for half | 1.5 | 1100*700*1300 |

| 6 | Screening belt | 0.75 | 5000*800*1000 |

| 7 | Hoist | 0.75 | 1000*500*3400 |

| 8 | store material feeding machine | 0.55 | 700*700*2200 |

| 9 | Butter grinding machine | 11*2 sets | 1000*350*900 |

| 10 | Storage tank | 200L | |

| 11 | Paste pump | 1.5 | 1200*300*350 |

| 12 | Mixing tank | 2.2 | 300L |

| 13 | Vacuum degassing tank | 2.2 | 300L |

| 14 | Paste pump | 1.5 | 1200*300*350 |

| 15 | Control cabinet | ||

| 16 | Pipeline |