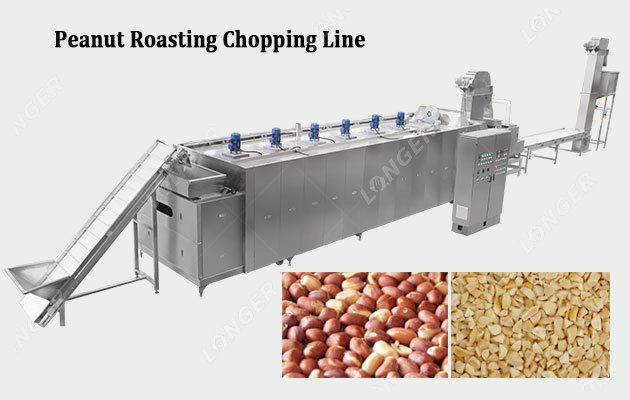

Automatic Peanut Roasting Chopping Production Line PLC Control

Material: Peanuts

Capacity: 500 kg/h

Loading Port: Qingdao Port

Description: The production line can complete the roasting, peeling and chopping of peanuts. Full machine automation.

Product Features

This peanut roasting line is mainly composed of peanut roasting machine, peeling machine, picking belt and peanut chopping line. Fully automatic production, the whole line is controlled by PLC cabinet, easy to operate.

The production capacity of this roasted peanut production line reaches 500kg per hour, and 1 t/h equipment is also available, which is suitable for medium and large peanut processing plants.

Peanut roasting and chopping process:

Peanuts - Lifting - Roasting - Cooling - Peeling - Picking - Chopping - Grading

Introduction of Peanut Roasting Chopping Line:

1. Peanut Roasting Machine

The roasting machine has roasting and cooling functions and is suitable for continuous production. It consists of a heating system, a cooling system and a transmission system. The temperature controller can realize automatic temperature control, and the roasted peanuts are uniform in color and without damage.

Advantages of the Roasted Peanut Production Line

- The hot air distribution adopts a specially designed air plate structure, so that the air volume acting on the material is more balanced and the baking is more uniform.

- 6 sets of 1.5kw circulating fans are used to increase the air volume and make the hot air circulate faster.

- The heating, baking and cooling zones are isolated to reduce unnecessary waste of baking heat.

- Three observation mirrors are added on the side, which can clearly observe the roasting state of peanuts, which is convenient for debugging equipment parameters.

- The thickness of the paving is easy to adjust, the operation is visualized, and it is more convenient.

2. Peanut Peeling Machine

The roasted and cooled peanuts go to the peeler. The peanut is divided into half by the extrusion of two rubber rollers and differential rubbing, the fan separates the detached red skin, and sieves out the germ, and the peanut crushed is discharged from the feeding port.

3. Picking Belt

Manual sorting. Unpeeled peanuts, minor defects, damaged peanuts, debris will be sorted out.

4. Peanut Chopping Line

The whole set of equipment consists of elevator, peanut chopper and screening machine. The cutted peanuts have uniform particle size, beautiful appearance, less material consumption, and the particle size can be adjusted, which can usually be divided into three or four grades. The size of the screen can be customized according to customer requirements.

Application Range of the Peanut Roasting Production Line:

Application Range of the Peanut Roasting Production Line:

This set of roasters and choppers is suitable for all kinds of nuts and legumes and has a very wide range of applications. Mainly used for peanuts, almonds, cashews, hazelnuts, soybeans, cocoa beans, melon seeds, nuts, wheat, barley, oats and other granular materials.

The roasted nuts and beans have an excellent taste, which is suitable for the consumption needs of the public and has a broad market prospect.

Technical Data

| No. | Name | Power(kw) | Dimension(mm) |

| 1 | Lifting Machine | 0.75 | Height:2000mm |

| 2 | Roasting and Cooling Machine |

4.4kw Gas Consumption: 10-12KG/H |

8500*2250*2600 |

| 3 | Lifting Machine | 0.75 | Height:2000mm |

| 4 | Peeling Machine | 1.5+0.75 | 1800*750*1300 |

| 5 | Picking Belt(4m) | 0.75 | 4000*700*1000 |

| 6 | Peanut Chopping Machine | 3.7 | 2080*1000*1700 |

| 7 | Vibrating Screen | 0.36 | 2400*1120*1020 |