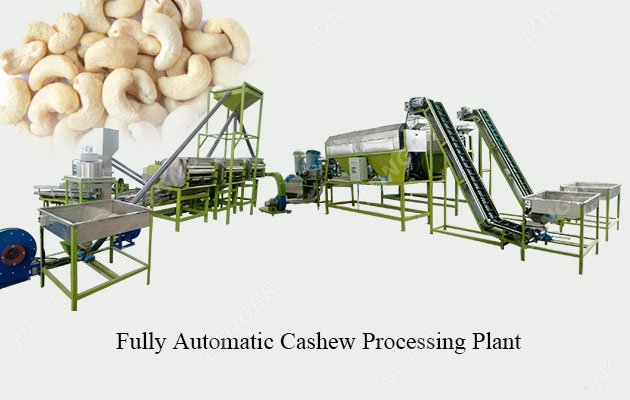

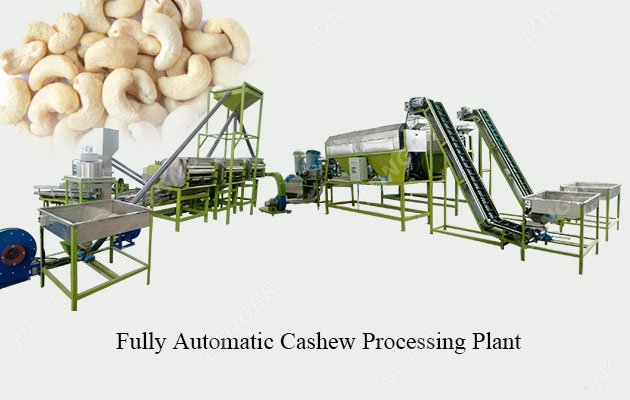

Fully Automatic Cashew Processing Plant Cost 3-10 Ton

Material: Raw Cashew Nuts

Capacity: 3-10 Ton Per Day

Loading Port: Qingdao Port

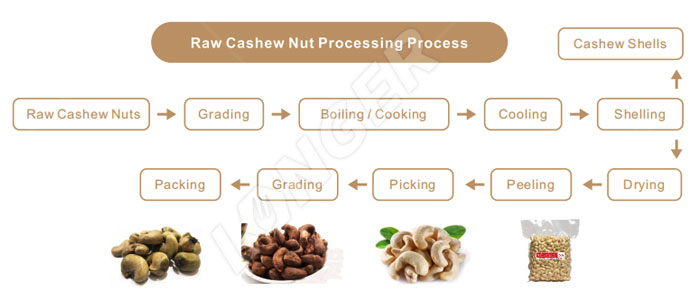

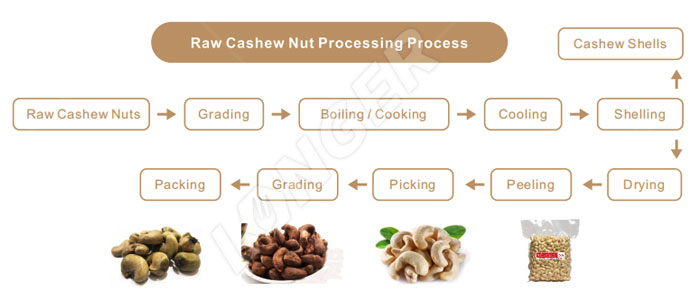

Description: The cashew nut processing plant can complete the whole process of raw cashew grading, cooking, shelling, drying and peeling.

Product Features

This fully automatic cashew processing plant includes raw cashew grading machine, cooking machine, cutting/shelling machine, dryer, peeling machine, etc. Advanced technology, the whole line is controlled by sections, and the electronic synchronous control system is easy to adjust. The production capacity can be selected from 3 tons to 10 tons per day.

Core Equipment in the Automatic Cashew Nut Processing Plant:

1. Raw Cashew Grading Machine

The classifier adopts a drum screen structure, and cashew nuts of different specifications are screened through different apertures, and the screening is accurate and efficient. Generally divided into 5 levels (below 18mm, 19mm, 21mm, 23mm, and above 24mm).

2. Cashew Cooker Machine

The graded raw cashews are placed in a high-pressure cooking pot with clean water for steam heating, heating temperature and time (1.5 steamed for about 25-28 minutes, normal pressure for about 35 minutes, temperature 90-100 °). Cooking can effectively separate the husk and the nut, so that the shell can be broken and the whole kernel rate of cashew nuts can be improved.

3. Raw Cashew Shelling Machine

The complete set of shelling equipment includes a feeding and distribution system, a cashew nut shelling machine, a vibration separation mechanism, a wind separation system, a centrifugal separation mechanism, a finished product conveying mechanism and a finished product screening mechanism. Advanced technology can effectively achieve multiple levels of cashew hulling and kernel separation.

4. Cashew Peeling Machine

The whole line includes a feeding machine, a loosening machine, a gas peeling machine, and a nut separator. The whole system combines mechanical and pneumatic technology as well as automatic feeding and half-size sorting functions, which can realize continuous peeling of nuts, separation of half and whole kernels, etc., with high peeling rate and low breakage rate.

Advantages of Cashew Processing Plant Cost

Core Equipment in the Automatic Cashew Nut Processing Plant:

1. Raw Cashew Grading Machine

The classifier adopts a drum screen structure, and cashew nuts of different specifications are screened through different apertures, and the screening is accurate and efficient. Generally divided into 5 levels (below 18mm, 19mm, 21mm, 23mm, and above 24mm).

2. Cashew Cooker Machine

The graded raw cashews are placed in a high-pressure cooking pot with clean water for steam heating, heating temperature and time (1.5 steamed for about 25-28 minutes, normal pressure for about 35 minutes, temperature 90-100 °). Cooking can effectively separate the husk and the nut, so that the shell can be broken and the whole kernel rate of cashew nuts can be improved.

3. Raw Cashew Shelling Machine

The complete set of shelling equipment includes a feeding and distribution system, a cashew nut shelling machine, a vibration separation mechanism, a wind separation system, a centrifugal separation mechanism, a finished product conveying mechanism and a finished product screening mechanism. Advanced technology can effectively achieve multiple levels of cashew hulling and kernel separation.

4. Cashew Peeling Machine

The whole line includes a feeding machine, a loosening machine, a gas peeling machine, and a nut separator. The whole system combines mechanical and pneumatic technology as well as automatic feeding and half-size sorting functions, which can realize continuous peeling of nuts, separation of half and whole kernels, etc., with high peeling rate and low breakage rate.

Advantages of Cashew Processing Plant Cost

- First use the latest advanced technology, the shelling rate of cashew nuts is ≥98%, the whole kernel rate is ≥91%, and the peeling rate of cashew kernels is more than 95%.

- The gas peeling form has the advantages of high peeling rate and low breakage rate.

- The parts in contact with cashew kernels are made of stainless steel, which ensures the hygienic conditions of food processing.

- For customized cashew processing plant, we will design and manufacture the equipment reasonably according to the characteristics of your factory and the corresponding process parameters.

- A variety of production capacities are available with different prices, we will provide you with the most competitive prices and save costs.

Technical Data

| No. | Name | Capacity(kg/h) | Power(kw) | Weight(kg) | Size(mm) | Qty |

| 1 | Grading Parts | 1000 | 2.25 | 1800 | 6000*1650*2300 | 1 |

| 2 | Cooking Machine | 600 kg/time | 0.75 | 1200 | 1200*1200*3750 | 1 |

| 3 | Steamer | 0.5t | / | 1250*1250*3700 | 1 | |

| 4 | Shelling Parts | 500 | 22 | 3500 | 8000*6850*2600 | 2 |

| 5 |

Drying Parts (steam heating) |

900-1000 kg/time | 3 | 2800 | 5250*2200*2300 | 2 |

| 6 | Humidifier | / | / | / | 800*800*700 | 3 |

| 7 | Peeling Parts | 200 | 3 | 1100 | 8000*1350*2700 | 1 |

| 8 | Kernel Grading machine | 200 | 0.75 | 350 | 2200*1100*1600 | 1 |

| 9 | Vacuum Packing Machine | / | 2.25 | 190 | 900*700*1800 | 1 |