300KG Small Cooking Oil Refinery Machine Low Cost

Material: Crude Oil

Capacity: 300 kg/batch/12h

Loading Port: Qingdao Port

Description: Special equipment for small-scale oil refinery plants. Used to refine various crude oils to produce high-quality edible oils.

Product Features

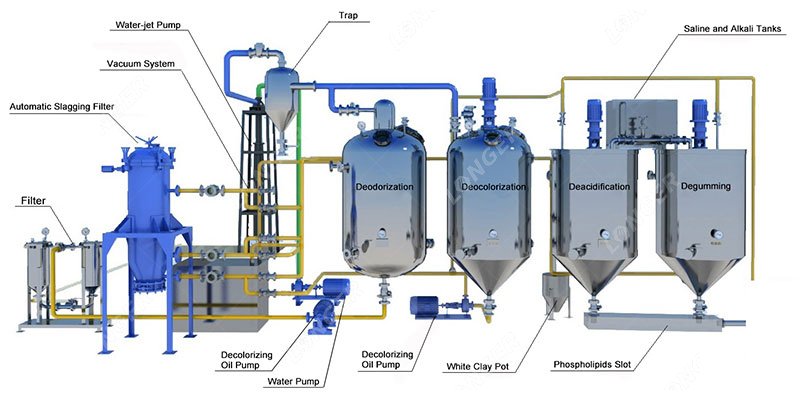

This set of small cooking oil refinery machine is an intermittent refining equipment, suitable for different types of oils, such as peanut oil, soybean oil, sunflower oil, etc. The refined oil can meet food safety requirements.

Complete set of combined equipment, low investment cost and small floor space. Self-provided heat source, electrical control, low energy consumption.

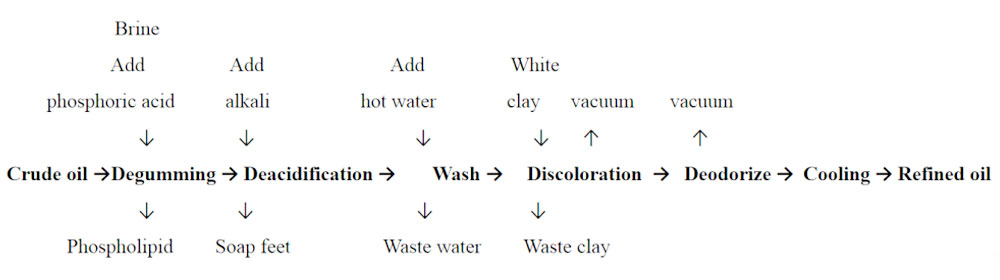

Cooking Oil Refining Process:

The unit mainly uses physical and chemical reactions to achieve different standards of refined oil (fourth grade oil, third grade oil, second grade oil and first grade oil).

- Degumming process: the use of hydrated phospholipids to absorb water and swell and flocculate into a colloid, while simultaneously adsorbing mechanical impurities to achieve the purpose of dephospholipid and impurity removal.

- Deacidification process: Use acid-base neutralization reaction to make free fatty acids form salts and dissolve in water, and then achieve the purpose of deacidification.

- Decolorization process: Use the strong adsorption capacity of activated carbon or activated clay to absorb the pigments in the grease to achieve the purpose of reducing the color of the grease.

- Deodorization process: Using the principle of distillation under negative pressure to remove odorous substances such as aldehydes, ketones, acids and other small molecules in the oil.

After the above steps, a qualified first-grade edible oil is finally obtained.

Advantages of Small Oil Refinery Machine:

- It adopts automatic temperature control and electric heating;

- The food contact surface is made of SUS304 material, which is resistant to acid and alkali corrosion under high temperature conditions, which is more in line with food safety requirements;

- Multipurpose. Only one system can refine peanut oil, palm kernel oil, coconut oil, sunflower oil, rapeseed oil and other oils;

- The quality of refined oil is controllable. The oil refining machine can be freely combined and can be used to produce fourth-grade oil, third-grade oil, second-grade oil and first-grade oil, with various functions;

- Standardized operation process, according to the established SOP can easily complete oil refining;

- The system has a simple structure, small floor space and easy installation.

Multi-capacity Available, Support Customization

We also supply cooking oil refinery machine with capacities of 500 kg, 1000 kg and 2000 kg. Refining equipment with various capacities can also be customized according to customer needs, laying the foundation for the subsequent promotion of larger refining equipment.

Email: serena@machinehall.com WhatsApp/Mobile: +8615515597212

Technical Data

| No. | Name | Quantity | Unit | Power(KW) | Remark |

| 1 | Washing tank | 1 | Piece | 0.55 |

Mirror SS304 (Electric Heating) |

| 2 | Alkali refining tank | 1 | Piece | 0.55 |

Mirror SS304 (Electric Heating) |

| 3 | Hot water alkaline water tank | 1 | Piece |

Mirror SS304 (Electric Heating) |

|

| 4 | White clay pot | 1 | Piece | Mirror SS304 | |

| 5 | Air compressor | 1 | set | 3 | Standard |

| 6 | Decolorization tank | 1 | Piece | 0.55 |

Mirror SS304 (Electric Heating) |

| 7 | Plate filter | 1 | set | ||

| 8 | Decolorized oil tank | 1 | piece | Mirror SS304 | |

| 9 | Deodorization tank | 1 | piece |

Mirror SS304 (Electric Heating) |

|

| 10 | Vacuum trap | 1 | piece | Mirror SS304 | |

| 11 | Steam generator | 1 | Set |

Q235 (Electric Heating) |

|

| 12 | Soda separator | 1 | piece | Mirror SS304 | |

| 13 | Finished product condenser | 1 | Set | Mirror SS304 | |

| 14 | Fine filter | 1 | Set | Mirror SS304 |